The 156 USB is our only gauge that includes a USB port that allows interface to a PC and data download via the included software. The ability to download readings to computer is ideal for professional detailers, laboratories and industrial users who wish to maintain and analyse records of readings taken. Other additional features of the 156 USB include its:

- Electronic menu system

- Continuous reading mode (read along a surface without lifting gauge from surface) as well as spot reading mode

- Selectable on screen statistics display: average, minimum, maximum, number of readings, standard deviation

- High and Low reading alarms

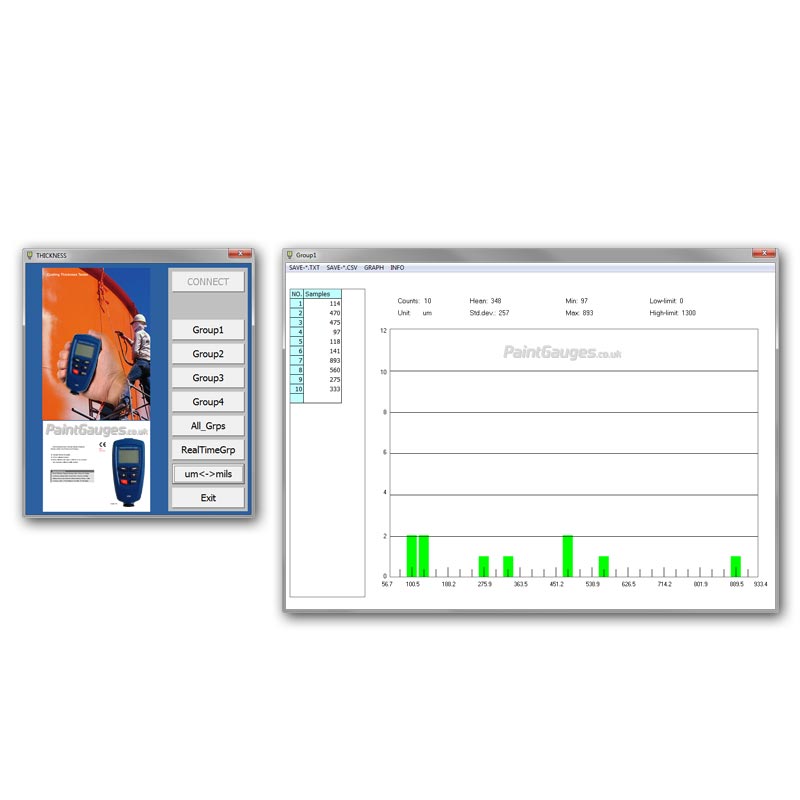

Readings taken with the 156 USB can be downloaded to a PC for storage or analysis. The gauge is connected to the PC via the supplied USB lead and the application software can then be used to download readings to the PC. The software can then be used to list, show statistics for and chart a group of readings. Additionally the readings can be exported (to a CSV or TXT file) for use in another application (such as Microsoft Excel) for further analysis. The gauge comes complete with driver and application software on CD, which is compatible with Windows 2000, XP, Vista and 7.